Automatic cross hole inspection for your manufacturing processes

Automatic cross-hole inspection not only promises increased efficiency and precision in manufacturing processes, but also a significant reduction in complaints.

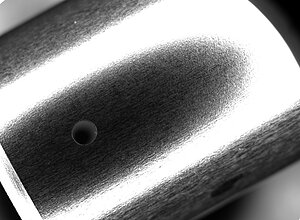

The latest development in this area shows process-reliable detection of defects in cross holes. Using the latest image processing technologies, our engineers have created a solution that takes the monitoring and control of cross holes in production processes to an unprecedented level.

How does this groundbreaking technology work?

The automatic cross-bore control is based on high-resolution cameras and specially developed algorithms. This camera are able to detect tiny details in the bores and identify the finest deviations from the given specifications. The algorithms are programmed to process this information in real time and provide immediate feedback.

The cross hole inspection is integrated as a module in visiTeach+.

What advantages does this technology offer?

1. Higher precision: Automatic cross hole inspection ensures unparalleled precision in quality assurance. Even the smallest deviations are detected before they can lead to quality problems.

2. Increase Efficiency: As technology reduces the need for manual inspection, manufacturing processes can be accelerated and automated, resulting in increased productivity.

3. Cost Reduction: By avoiding complaints and downstream quality issues, companies can achieve significant savings.

4. Higher product quality: End products will reliably meet quality standards, increasing customer satisfaction and strengthening brand image.

Automatic cross hole inspection has applications in a variety of industries, including automotive, aerospace and medical. Wherever precision and quality are crucial, this process will provide enormous added value.

This technology will not only optimize existing processes but also open the door to new testing opportunities.

The future of manufacturing looks bright as innovations like these help us continue to push the boundaries of what is possible.