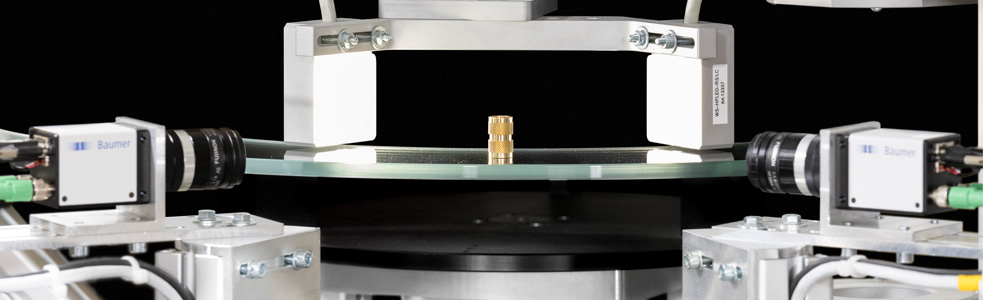

Variable, optical inspection and sorting machine with glass disc for many different geometries and inspection features

Performance features:

- Output up to 800 parts/min

- Up to 12 cameras in 6 inspection positions

- Dimensional and attributive features

- Tolerances up to ±0.01mm

- Additional sensors possible

- (e.g. eddy current, confocal, ...)

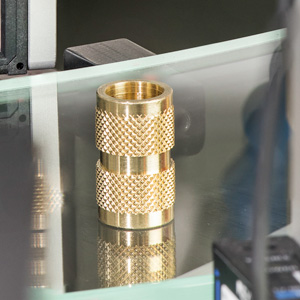

Inspection parts

Parts range

- standing parts

- up to height 50 mm, diameter 60 mm

- Aspektverhältnis (Höhe zu Durchmesser) bis 3:1 möglich

Parts alignment

- Radial positioning depending on part diameter

- Automated possible with ACO

- Description see Accessories »»

Parts detection

- Light barrier with laser curtain

Ejection

- Up to 5 pneumatic discharges possible

- Automated pressure adjustment possible with APC

- Description see Accessories »»

Inspection procedure

Measuring:

- Telecentric beam path for precise measurement from above and from the side

- Second camera possible on interchangeable slides for different part sizes

Assess

- Attributive inspection of surface, flat surface with 2D and 3D methods from above and/or below

Presence:

- Presence of internal thread, knurl, etc. from above and/or below

Surfaces:

- Assessment of surface, lateral surface with 360° optics from above and/or below

Turning chips

Examples:

- 4 cameras inclined in a star shape for chips in inner groove

- 2 cameras ± 60° to the camera from the side for chips in outer groove

Specials:

- Sensor for hardness testing

- Sensor for drilling depth